Digitalization in process development

For any production process, there are two key attributes, namely scientific knowledge and technical know-how. Scientific knowledge comprises process development and validation, whereas technical know-how involves process definition and scale-up for commercial production. Multiple organizations need to collaborate to understand the economical and process constraints and then offer a digital solution that focuses on development of a new model, and validation and renewal of the existing models. This exercise involves integrating information flow, manufacturing, and automation to deliver an optimal commercial process (1).

Digitalization is fuelling the shift from paper-based records to digitalized central databases, making data storage and handling more systematic and efficient. This, in turn, facilitates knowledge transfer across products, processes, or scales. This knowledge transfer can be channeled through process models that can be mechanistic, statistical, machine learning, or hybrid. Digital twins are becoming quite popular as a potential source of data acquisition. In the new paradigm, process development is followed by testing and learning wherein learning is undertaken by artificial intelligence. The equipment can be interfaced with the corresponding digital twins using sensors and actuators such that the real time data is fed to the digital twins and the in silico predicted can be employed for control of the equipment. By transforming data into an intelligence-supporting decision-making tool, it is easy to realize the longstanding regulatory initiatives of process analytical technology (PAT) and quality by design (QbD) as well as Industry 4.0.

In upstream processing, researchers have demonstrated the value of automation in microscale bioprocesses (2). In microbial cell cultures, scale down models such as micro well plates (3) and deep well plates are employed, whereas shake tubes/flasks are widely used in mammalian cultures (4). However, most of these systems lack or at best offer limited abilities for process monitoring or control. Researchers have attempted to create mechanistic models that can predict the impact of major process variables (5) on the critical quality attributes (CQAs) (6); however, these mechanistic models are rarely used by manufacturers due to their complexity and lack of accuracy. As a result, simple data-driven, dynamic process models that are based on various machine learning techniques are more commonly used in the industry. Over the past decade, manufacturers have been increasingly using hybrid models (7) as these offer better model accuracy and reliability together with alignment with Industry 4.0.

Similar studies have also been conducted in downstream processing unit operation. Data-driven models have been used for predicting product recovery and optimization (8). Recently, a hybrid modeling approach, combining both mechanistic modeling and data-driven modeling, has been shown to offer a multitude of benefits. For chromatography, relating data from sensor with the CQAs of the process has been shown to improve CQA predictions with errors less than 5% (9). In two-column capture chromatography, dynamic control can be obtained using adaptive model-based control strategy that led to process yield of more than 85%. The data from high performance liquid chromatography (HPLC) coupled with chromatography equipment enabled the control decision making. Also, the desired charge variant composition of the final could be obtained (10). For flow-through chromatography, plate model, mass balance model, and general rate model can be used to capture phases, generate breakthrough curves, and predict product concentrations. These models can be coded in MATLAB, CADET or ChromX platforms and can help in generating insights that can be converted into actionable control decisions.

For dynamic inline pH adjustment in continuous processing, model-based control strategy has been employed by predicting the pH profile between the chromatography wash and the elution steps, thereby facilitating integration of capture chromatography with the viral inactivation operation (11). For formulation, a model for predicting volumetric concentration factor across single pass tangential flow ultrafiltration (SPTFF) can be used to develop real-time automated monitoring and a control solution. In a case study, it was seen that integrating a distributed control system with the sensors and control elements provided a means to implement QbD and PAT in continuous manufacturing (12). In addition to process development, models help in process scale up by simulating a process under multiple scenarios, identifying critical patterns and inconsistencies. In case of filtration, the Aspen Custom Modeler software has been used to generate a mechanistic model or a hybrid model for model-predictive control. These models can capture trends and predict volumetric flow, flux, and pressure across membranes (13).

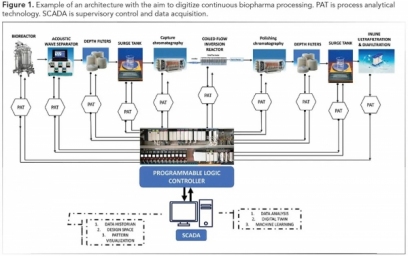

Implementation of these approaches requires setting up reliable communication protocols and user-friendly interfaces between the unit operations with a robust supervisory control and data acquisition (SCADA) system (14). The industry realizes that there is a limit on the number of experiments that is feasible, and, hence, extensive use of methodologies such as design of experiments and multivariate data analysis is being done (15).

Use of advanced data analytics is now extending to analysis of data from the large number of analytical and functional characterization assays that any manufacturer performs routinely. This has greatly facilitated efficient extraction of the required knowledge from these large datasets (16).

Digitalization in manufacturing

Owing to technological advancements over the past decade, automation and integration of multiple-unit operations is becoming commonplace with manufacturers implementing continuous processing for some of the unit operations if not for the end-to-end process. What remains a challenge is automation and control of such an operation. A high level of automation is required to ensure continuous flow of material from end-to-end as well as during start up and shutdown operations. With the large number of CQAs that are associated with biotherapeutic products, their monitoring across the various process steps can be a challenging task. Digital solutions have emerged as efficient means for consolidating process knowledge and experience and thereby minimize process failures.

In the biopharma industry, distributed control system (DCS) and programmable logic controller (PLC) with SCADA system are two of the commonly used automation platforms. DCS has centralized set point management, control, and data acquisition. The PLC/SCADA platform has localized control of unit operations and centralized set point management and data acquisition. One of the software (python-based) programs named Orbit acts like a digital twin and offers customized real-time control solutions for an integrated system with extra functions such as monitoring, simulation, and graphical visualization (17). It has two layers, one for communicating and one for real-time execution and multiple units with a defined protocol. Each unit communicates with one system, and communication between units is handled by a real-time kernel. A more common approach is to combine DCS with PLC/SCADA (18) to design a platform that can automate data pre-processing and analysis, reduce human intervention, automate process control, and perform fault detection to improve process efficiency.

However, there are many attributes such as charge variant, aggregates, host-cell proteins, and bioburden that cannot be measured online at present and require sampling and offline analysis (19). Creation of PAT-like approaches for analysis of these attributes will greatly facilitate their real-time monitoring and control. Researchers are attempting to use in-line spectroscopic tools such as infrared, near infrared (NIR), and Raman spectroscopy to acquire data at different process stages, followed by chemometric analysis for gaining better prediction and control capabilities (20). In periodic counter-current chromatography, sensor data from ultraviolet absorbance connected at the primary load column can be used to control column loading (21).

Advanced control systems include automatic responses like alarm, messages assurance, and PAT-based advanced strategies so that the system stays within the predefined design space as required. In one of the PAT applications for SPTFF, empirical model was used to determine the design space to predict feed flowrate and concentration factor relationships leveraging in line concentration, flowrate, pressure sensor and data from NIR (20). PID-based flux control strategy was also designed to control and schedule the process for longer runtimes. Recently, a python-based control strategy has been proposed for real-time adjustment of integrated downstream to optimize productivity used data from multiple sensors (22). The strategy was designed to handle deviations in titer from 1 g/L to 7 g/L by selecting a pre-programmed set of methodologies designed as per the requirements. In another study, integrated process model correlating two process related impurities with two product-related impurities was developed to capture process development and design data and predict out-of-specification batches (23). The strategy was demonstrated as being effective in managing continuous data and thereby facilitating risk-based decision making.

Digitalization in quality assurance/quality control

Digitalization is also impacting QA and quality control. Its implementation results in higher quality standards and efficiencies. It helps to increase transparency and traceability in the process chain, automates data acquisition and management, and improves visibility in the platform. Adhering to regulatory compliances is critical during biopharma manufacturing. One of the critical FDA guidance documents that applies to digitalization efforts is that of Part 11 of Title 21 of the Code of Federal Regulations (Electronic Records; Electronic Signatures). This document pertains to maintenance of the process data that are acquired. In addition, QbD and good manufacturing practice ordinances demand clarity in the digitalization approach in terms of virtual process design and its acceptance by regulatory agencies; intellectual property rights and information technology security; and probable ways to handle regulatory barriers.

Perspective

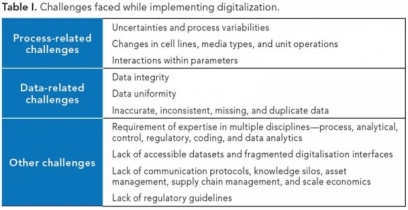

The biopharma industry is embracing Industry 4.0 and undergoing digitalization with the hope of achieving reduced product-to-market timelines and improving process efficiency, yield, and productivity. However, widespread adoption on the manufacturing floor is awaited and requires successful resolution of some of the major challenges. Implementing digital solutions required intimate collaboration amongst multiple functions and experts. Regulatory agencies are also in the process of familiarizing themselves with the various facets of digitalization, and only then can they propose effective guidance. Thus, at the moment there is need for designing flexible, modular, and agile processes with strategies to implement PAT solutions at the development stage (Figure 1).

It should be pointed out that the biopharma industry is yet to fully adopt automated systems, which is a requirement for Industry 3.0, and will thus be a requirement for Industry 4.0. Thus far, the majority of research efforts directed toward developing digital twins, model-based control, and soft sensors have focused on individual unit operations. There is a need to establish smooth communication among unit operations, transfer, and storage of data centrally in standard data format. This is an activity that requires extensive human intervention at the moment, partly because of a lack of standards across suppliers of process and analytical equipment. Initiatives such as Internet of Things and cloud computing offer interesting possibilities for digitalization.

Despite the numerous challenges, there are ample signs that the industry is moving in the right direction. Researchers are increasingly exploring the role that digital twins and advanced data analytics can play in biopharma manufacturing. In addition, single-use technologies that require reduced human intervention are seeing adoption. Developing cyber physical production systems with automated process control, process diagnosis, and prognosis with an external platform to inform the operator about the progress of the process has been shown to be an effective enabler of this transition.

It is important that regulatory agencies offer greater support in this transition, offering clarity on implementation, execution, characteristics, and properties of these technologies along with the protocols that need to be followed for validation and approval. This will bring clarity to the manufacturers and aid adoption.

References

1. Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD); Zhangjiajie: IEEE; 2016. DOI: 10.1109/FSKD.2015.7382284

2. Knevelman, C.; Davies, J.; Allen, L.; et al. High-Throughput Screening Techniques for Rapid PEG-Based Precipitation of IgG4 mAb from Clarified Cell Culture Supernatant. Biotechnol. Prog. 2010, 26, 697–705.

3. Dörr, M; Fibinger M. P. C.; Last, D.; et al. Fully Automatized High-Throughput Enzyme Library Screening Using a Robotic Platform. Biotechnol Bioeng. 2016, 113 (7), 1421–1432. DOI: 10.1002/bit.25925.

4. Bielser, J. M.; Domaradzki, J.; Souquet, J.; Broly, H.; Morbidelli, M. Semi-Continuous Scale-Down Models for Clone and Operating Parameter Screening in Perfusion Bioreactors. Biotechnol Prog. 2019, 35 (3), e2790. DOI: 10.1002/btpr.2790.

5. Wolf, M.; Bielser, J. M.; Morbidelli, M. Perfusion Cell Culture Processes for Biopharmaceuticals: Process Development, Design, and Scale-up; Cambridge University Press, 2020. DOI: 10.1017/9781108847209

6. Hutter, S.; Villiger, T. K.; Brühlmann, D.; et al. Glycosylation Flux Analysis Reveals Dynamic Changes of Intracellular Glycosylation Flux Distribution in Chinese Hamster Ovary Fed-Batch Cultures. Metab. Eng. 2017, 43, 9–20. DOI: 10.1016/j.ymben.2017.07.005

7. O’Brien, C. M.; Zhang, Q.; Daoutidis, P.; Hu, W. S. A Hybrid Mechanistic Empirical Model for In Silico Mammalian Cell Bioprocess Simulation. Metab. Eng. 2021, 66, 31–40. DOI: 10.1016/j.ymben.2021.03.016.

8. Nikita, S.; Tiwari, A.; Sonawat, D.; Kodamana, H.; Rathore, A. S. Reinforcement Learning-Based Optimization of Process Chromatography for Continuous Processing of Biopharmaceuticals. Chem. Eng. Sci. 2021, 230, 116171. DOI: 10.1016/j.ces.2020.116171 116171

9. Nikita, S.; Thakur, G.; Jesubalan, N. G.; et al. AI-ML Applications In Bioprocessing: ML as an Enabler of Real Time Quality Prediction in Continuous Manufacturing of Mabs. Computers & Chemical Engineering 2022, 164,107896. DOI: 10.1016/j.compchemeng.2022.107896

10. Tiwari, A.; Masampally, V. S.; Agarwal, A.; Rathore, A. S. Digital Twin of a Continuous Chromatography Process for mAb Purification: Design and Model-based Control. Biotechnol. Bioeng. 2023, 120, 748–766. DOI: 10.1002/bit.28307

11. Thakur, G.; Ghumade, P.; Rathore, A. S.Process Analytical Technology in Continuous Processing: Model-based Real Time Control of pH Between Capture Chromatography and Viral Inactivation for Monoclonal Antibody Production. J. Chromatogr. A 2021, 1658, 462614. DOI: 10.1016/j.chroma.2021.462614

12. Thakur, G.; Masampally, V.; Kulkarni, A.; et al. Process Analytical Technology (PAT) Implementation for Membrane Operations in Continuous Manufacturing of mAbs: Model-Based Control of Single-Pass Tangential Flow Ultrafiltration. AAPS J 2022, 24, 83. DOI: 10.1208/s12248-022-00731-z

13. Krippl, M.; Dürauer, A.; Duerkop, M. Hybrid Modeling of Cross-Flow Filtration: Predicting the Flux Evolution and Duration of Ultrafiltration Processes. Sep. Purif. Technol. 2020, 248, 117064.

14. Narayanan, H.; Luna, M. F.; von Stosch, M.; et al. Bioprocessing in the Digital Age: The Role of Process Models. Biotechnol. J. 2019, 15 (1),1900172. DOI: 10.1002/biot.201900172

15. Sawatzki, A.; Hans, S.; Narayanan, H.; et al. Accelerated Bioprocess Development of Endopolygalacturonase-Production with Saccharomyces cerevisiae Using Multivariate Prediction in a 48 Mini-Bioreactor Automated Platform. Bioengineering 2018, 5 (4), 101. DOI: 10.3390/bioengineering5040101

16. Anane, E.; Sawatzki, A.; Neubauer, P.; Cruz-Bournazou, M. N. Modeling Concentration Gradients in Fed-batch Cultivations of E. Coli—Towards the Flexible Design of Scale-Down Experiments. J. Chem. Technol. Biotechnol. 2019, 94 (2), 516–526. DOI: 10.1002/jctb.5798

17. Andersson, N.; Fons, J. G.; Isaksson, M.; et al. Methodology for Fast Development of Digital SolutionsiIn Integrated Continuous Downstream Processing. Biotechnol Bioeng. 2023. DOI: 10.1002/bit.28501

18. David, L.; Schwan, P.; Lobedann, M.; et al. Side-by-side Comparability of Batch and Continuous Downstream for the Purification of Monoclonal Antibodies. Biotechnol. Bioeng. 2020, 117 (4), 1024–1036.

19. Fisher, A. C.; Kamga, M. H.; Agarabi, C.; et al. The Current Scientific and Regulatory Landscape in Continuous Biopharmaceutical Manufacturing. Trends Biotechnol. 2019, 37 (3), 253–267.

20. Thakur, G.; Thori, S.; Rathore, A. Implementing PAT for Single-pass Tangential Flow Ultrafiltration for Continuous Manufacturing of Monoclonal Antibodies. J. Membr. Sci. 2020, 613, 118492. DOI: 10.1016/j.memsci.2020.118492

21. Chmielowski, R.A.; Mathiasson, L.; Blom, H.; et al. Definition and Dynamic Control of a Continuous Chromatography Process Independent of Cell Culture Titer and Impurities. J Chromatogr A. 2017, 1526, 58–69. DOI: 10.1016/j.chroma.2017.10.030

22. Thakur, G.; Ghumade, P.; Rathore, A. S. Process Analytical Technology in Continuous Processing: Model-based Real Time Control of pH Between Capture Chromatography and Viral Inactivation for Monoclonal Antibody Production. J Chromatogr A. 2021, 1658, 462614. DOI: 10.1016/j.chroma.2021.462614

23. Zahel, T.; Hauer, S.; Mueller, E. M.; et al. Integrated Process Modeling—A Process Validation Life Cycle Companion. Bioengineering 2017, 4 (4), 86. DOI: 10.3390/bioengineering4040086.

About the authors

Anurag S. Rathore, asrathore@biotechcmz.com, is a professor in the Department of Chemical Engineering, and Saxena Nikita is a post-doctoral fellow; both at the Indian Institute of Technology Delhi, India.

Article Details

BioPharm International

Volume 36, No. 11

November 2023

Pages: 25–29

Citation

When referring to this article, please cite it as Rathore, A. S.; Nikita, S. Digitalization: The Route to Biopharma 4.0. BioPharm International 2023, 36 (11), 25–29.