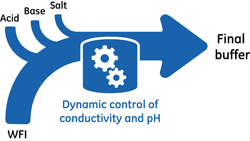

Preparation and storage of the large number of buffers required for biopharmaceutical production can be a challenge, particularly in large production scale. In this application note, we show how in-line conditioning (IC) can help reduce the number of hold tanks and floor space needed for buffer preparation and storage. With IC, buffers of desired formulations are prepared from smallvolume single-component stock solutions at the time of need. Formulating buffers from single-component stock solutions eliminates the need of conductivity and pH post-adjustments and adds the flexibility of on-demand production of different buffer formulations from the same stock solutions, simplifying buffer preparation. Compared with using manually formulated 1× buffers, our results show that the total tank volume could be reduced up to 90% and the footprint by 40% using IC.

Preparation and storage of the large number of buffers required for biopharmaceutical production can be a challenge, particularly in large production scale. In this application note, we show how in-line conditioning (IC) can help reduce the number of hold tanks and floor space needed for buffer preparation and storage. With IC, buffers of desired formulations are prepared from smallvolume single-component stock solutions at the time of need. Formulating buffers from single-component stock solutions eliminates the need of conductivity and pH post-adjustments and adds the flexibility of on-demand production of different buffer formulations from the same stock solutions, simplifying buffer preparation. Compared with using manually formulated 1× buffers, our results show that the total tank volume could be reduced up to 90% and the footprint by 40% using IC.

September 14, 2016