Annual study shows technical expertise is not enough.

Aug 1, 2014

By: Eric Langer

BioPharm International

Volume 27, Issue 8, pp. 12-14

Contract manufacturing organizations (CMOs) should have the technical expertise to be considered by clients for partnerships. As results from BioPlan Associates’ 11th Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production (1) show, however, it’s no longer enough for CMOs to lay claim to technology, regulatory compliance, and IP protection expertise, as these increasingly become non-negotiable issues.

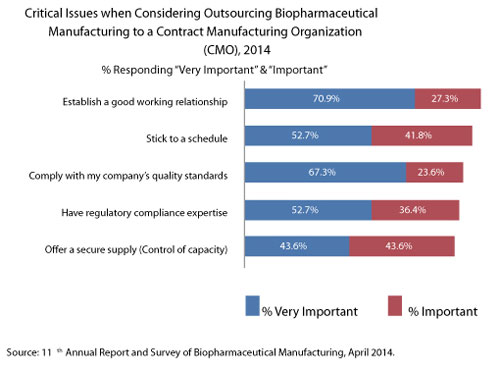

Sponsors today are demanding high levels of professionalism, performance, and effectiveness in managerial areas to accompany CMOs’ technical expertise. Indeed, when BioPlan surveyed 238 industry decision-makers from around the world about the critical issues they consider when selecting a CMO, a leading 71% said it was ‘very important’ that they be able to establish a good working relationship--with another 27% indicating this to be important (see Figure 1). In other words, virtually all decision-makers these days recognize the importance of a good working relationship.

Figure 1: Selected outsourcing issues: biomanufacturing by CMOs.

Figure 1: Selected outsourcing issues: biomanufacturing by CMOs.

This consideration has been moving up the rankings over the years. Of the 19 factors assessed, it was the fourth-most important back in 2006, before moving to the second spot in 2010 and now the top position by a fair margin. The next-most recognized factor this year was sticking to a schedule, deemed at least important by almost 95% of survey respondents. While this would seem intuitively obvious, the fact that this issue continues to appear year-after-year, suggests little is being done within the industry to address the problems.

Clearly, as this highly technical industry matures, customer service and establishing good client-vendor relationships are being perceived as more important attributes. But there are multiple factors that can jeopardize them. The CMO market--particularly for non-commercial scale manufacture--is competitive. CMOs are juggling multiple projects at the same time, and when clients select the lowest bidder, it’s not hard to understand that some CMO projects may not keep to schedule, despite everyone’s careful projections and planning. Add to this the uncertain nature of process development and problems that invariably arise, and it is easy to see how scheduling can be challenging.

That doesn’t make scheduling any less important, of course. Even small-market biopharmaceuticals typically involve sales of at least $200 million/year, such that each delayed work day in getting a product to market can represent a loss hundreds of thousands of dollars in sales, if not millions. As a result, clients and CMOs want to plan ahead and reserve enough time for crucial methods and technology transfer activities, as these almost always take longer than expected.

Selecting a CMO is challenging

Selecting the right CMO is a labor-intensive process, and with good reason. As sponsor companies increasingly outsource high-value activities previously deemed core in-house ones, they must take greater pains to ensure that they pick the right partnerships. Clients are seeking an increasing volume of available information about CMOs before they begin their due diligence. This type of vetting process allows for potential problem areas and questions to be identified at an early stage. As a result, it can take three or more months to build a rapport and start a project. And as the BioPlan study indicates, these first few months are crucial for both parties to build trust and a sound relationship. That relationship requires cooperation and flexibility, as well as the ability to understand the other side so as not to make unreasonable demands.

The CMO’s perspective

CMOs themselves have something to say about all this as well. In past years, BioPlan has found widespread complaints from CMOs regarding excessive client demands such as:

"Clients don’t build in sufficient time for the project (unrealistic timeframes)”

"Clients want to contain cost by doing limited development runs, but still expect successful full-scale manufacturing”

"Clients expect us to resolve the most difficult scientific or technical problems.”

Last year, each of those complaints was cited by at least 9 in 10 CMOs as being a “very” or “somewhat common problem.” Each problem had also been cited by a larger share of respondents than in prior years.

These are issues that can presumably be dealt with or even avoided if the contracting parties invest the effort to build solid relationships. But the data suggest that from the CMO perspective, clients have unrealistic expectations and simply may not be familiar with complexity of CMO operations--this suggests CMOs need to spend time upfront clarifying the overall project. The results also suggest that the majority of biomanufacturers, who are under increasing cost and time pressures, are pushing that stress onto their CMOs, potentially due to a lack of experienced staff dealing with CMOs and bioprocessing outsourcing.

Sponsors want CMOs to effectively handle tough issues

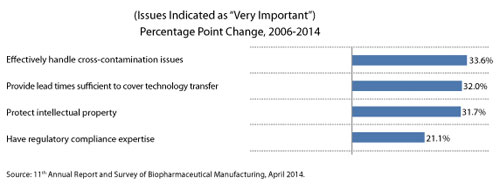

CMOs are being increasingly asked to quickly resolve tough problems, including cross-contamination issues. When BioPlan evaluated the changes over the years in how important clients/sponsors have considered various factors when selecting a CMO, we found a sizable increase in the share of respondents indicating that it’s “very important” that CMOs “effectively handle cross-contamination issues.” That consideration rose from 26.4% of respondents in 2006 to 60% this year, with that 33.6% point change the largest of any factor (see Figure 2).

Figure 2: Selected outsourcing issues: response shifts over time, 2006-2014.

Figure 2: Selected outsourcing issues: response shifts over time, 2006-2014.

Close behind, “provide lead times to cover technology transfer” (+32% since 2006) and “protect intellectual property” (+31.7%) have also seen considerable increases in client concern, potentially due to heightened perception of these risks.

By contrast, factors that have become crucial to fewer respondents over the years include having production platforms relevant to the client’s product. This is likely due to most CMOs having probably worked with many of their own and clients’ production platforms, and should become less of an issue over time as production platforms continue to increase and become more standardized. Capacity-related concerns in the context of CMOs have also decreased, with this likely associated with the current lack of any industry-wide capacity shortages and with CMOs simply not seeking or taking on projects beyond their capacity.

The ideal CMO

Results from the BioPlan study show that clients continue to seek better relationships with CMOs, and that reliability is a key trait they look for in their partners. Technical considerations obviously are paramount, too--there should not be a big difference between results at small scale and large scale when a CMO has been engaged, and clients will always demand expertise and quality.

But the trends in the data suggest that as the CMO market becomes more competitive and globalized, these sorts of qualities are being seen as prerequisites, and that questions of efficiency, timeliness, and reliability are coming to the fore. In essence, the technical expertise gets the CMO a seat at the table, but nowadays it’s the relationship that will seal the deal.

Reference

1. BioPlan Associates,11th Annual Report and Survey of Biopharmaceutical Manufacturing Capacity and Production (Rockville, MD, April 2014).

Eric Langer is president of BioPlan Associates, tel. 301.921.5979, elanger@bioplanassociates.com, and a periodic contributor to Outsourcing Outlook.

Eric Langer is president of BioPlan Associates, tel. 301.921.5979, elanger@bioplanassociates.com, and a periodic contributor to Outsourcing Outlook.